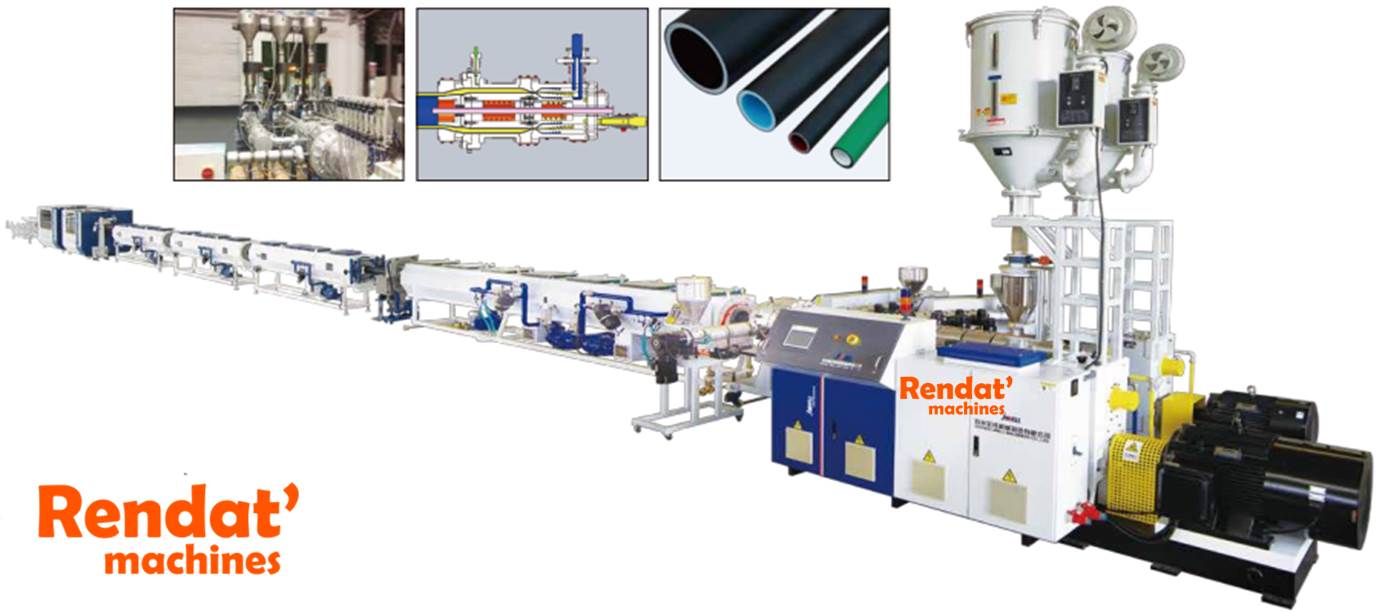

PPR25-110 Single Layer Pipe Extrusion Line

“Technical Specification for Single Layer Pipe Production Line”

RD-PPR25-110 Single Layer Pipe Extrusion Line Technical Specification RD-PPR25-110

Main Details of this Line |

|

| Design Output: | 150-180kg/h |

| Recommended Raw Material: | PPR materials |

| Above Outputs are under the conditions of: | Ambient temperature < 35°C and Sea Level Under 1000m (Any dissatisfaction on above conditions would cause output reduction). |

| Pipe Application: | Supply hot water and cool water |

| Operators Side: | On extrusion direction left side |

| Color Strips: | 2 lines |

| Pipe Color: | Green |

| Extrusion height: | 1000mm |

| Note: | No quoted equipment from customer’s side |

“Line Specification and Pressure Rating”(Pipe Size and Pressure Grade – Executive Standard: CJ/T258-2007) |

||||||

|

NO. |

Bush O.D. External Diameter ( mm ) | PN16 | PN20 | Mouth Die Quantity | Core Die Quantity | Calibrator

Quantity |

|

1 |

25 |

√ | √ | 1 | 2 | 1 |

| 2 | 32 | √ | √ | 1 | 2 |

1 |

|

3 |

40 | √ | √ | 1 | 2 | 1 |

| 4 | 50 | √ |

√ |

1 |

2 | 1 |

| 5 | 63 | √ | √ | 1 | 2 |

1 |

|

6 |

75 | √ | √ | 1 | 2 |

1 |

| 7 | 90 | √ | √ | 1 | 2 |

1 |

| 8 | 110 | √ | √ | 1 | 2 |

1 |

Main Conditions and Main Technical Performance |

|

1) Environment Condition |

|

| Best Location: | Location Indoors |

| Best Power Supply: | Power Supply Safe Area |

| Suitable Humidity Degree: | ≤95% (equals or less than ≤95%) |

| Suitable Temperature | 0-35℃ (between 0-35℃) |

2) Work Condition |

|

| Supply Voltage: | 3 x380V N PE, 50HZ |

| Voltage tolerance: | 10%, -10% |

| Control Voltage: | 24V DC / 220V AC |

| Total Power: | 130KW |

| Cooling Water: | ≤20℃, ≥0.3Mpa, ~3T/h |

| Compressed Air: | 0.3m3/min, >0.5Mpa |

| Total Length: | 38m |

3) Main Technical Performance |

|

| Material: | PPR |

| Output: | JWS65×33 Extruder = 150-180kg/h

JWS25×25 Extruder = 3-5kg/h |

| Output Note: | The output of this line capacity varies with the materials and the operation conditions as well. |

| Line speed: | 1.3~13m/min (according to the thickness and operation condition). |

No |

Quantity |

List of the Production Line |

Price (USD) |

1 |

1 | Automatic feeder and drier | |

2 |

1 |

JWS65×33 Single Screw Extruder |

|

3 |

1 |

JWS25×25 Color Strip Co-Extruder |

|

4 |

1 |

Mold(including, core die, mouth die, heater and calibrator) |

|

5 |

1 | Vacuum Tank (6000mm) | |

6 |

2 |

Cooling Tank (6000mm) |

|

7 |

1 |

Haul-off unit |

|

8 |

1 |

Cutter |

|

9 |

1 |

Stacker |

|

10 |

1 |

Electric control system |

|

11 |

1 |

Spare Parts |

|

12 |

Total Price |

||

Important Notes |

|

| Production Time: | 60 days after receiving advance payment. |

| Payment Terms: | 30% advance payment by T/T, 70% payment should be paid by T/T before shipment. |

| Warranty: | One year after installation. |

| Testing: | Test one diameter and testing material provided by customer. |

“Technical Descriptions”

1. (65×33 – Single Screw Extruder):

“Design Output: 150 – 180kg/h”

1.1. Automatic Feeder |

1.2. Drying Hopper |

||

| Feeding Type: | Vacuum Suction | Hopper Volume: | 100kgs |

| Drying Type: | Automatic Hot Wind | Heating Power: | 6kw |

| Capacity: | 200kg/h | Fan Power: | 0.24kw |

| Hopper Material: | Stainless Steel | ||

1.3. Screw and Barrel |

1.4. Gear Box |

||

| Diameter: | 65 | Made in: | Made in China |

| L/D: | 33 | Brand: | Jiang Yin |

| Material: | 38CrMoAlA | House Material: | QT200 |

| Heat Treatment: | Nitride (5-150rpm) | Gear Type: | Helical gears |

| Heating: | Ceramic Heater | Gear Material: | 20CrMnTi |

| Heating Zone: | 6zones | ||

| Heating Power: | 3kw X 5zones

2.2kwX1zones |

||

| Temperature Control Range: | 50-300℃ | ||

| Cooling Zones: | 5zones | ||

| Fan Power: | 0.25kwX5zones | ||

| Cooling Media: | Air Cooling | ||

1.5. AC Motor |

1.6. Drying Hopper |

||

| Power: | 75kw, Siemens or WEG Brand | Screen Type: | 12inch SIEMENS Touch Screen |

| Drive: | ABB inverter | CUP: | S7-1200 PLC |

| Operating Menu: | English & Chinese | ||

| Small Air Switch: | Schneider Brand | ||

| Main Air Switch: | CHNT Brand | ||

| Extruder Barrel Heater: | With Cotton Insulation | ||

| Fan: | With LINGNAN Strong Fan | ||

2. (25×25 – Color Strip):

“Co-Extruder”

2. Co-Extruder |

2.1. Hopper |

||

| Design Output: | 3-5kg/h | L: | 18L |

| Dimension: | 1100x600x1050mm | Material: | Stainless Steel |

| Weight: | 300kgs | ||

2.2. Screw and Barrel |

2.3. Gear Box |

|||

| Diameter: | 25 | Made in: | China | |

| L/D: | 25 | Brand: | Redsun | |

| Material: | 38CrMoAlA | House material: | QT200 | |

| Heat treatment: | Nitride 2-20rpm | Gear type: | Helical gears | |

| Heating: | Ceramic heater | Gear material: | 20CrMnTi | |

| Heating zone: | 2 zones | Gear surface treatment: | Quenching | |

| Heating power: | 1.8kw X 2zones | |||

| Temperature control range: | 50-300℃ | |||

2.4. AC Motor |

2.5. Electrical System |

|||

| Power: | 1.1kw | Integrated With Main Extruder | ||

| Drive: | ABB inverter | |||

3. Mold (including, core die, mouth die, heater and calibrator)

Mold (including, core die, mouth die, heater and calibrator) |

|

| Moulds Type: | Spiral Runner, Changeable and Polished Mouth Die & Mandrel |

| Material: | High Quality Alloy Steel |

| Heating Zone: | 6 Zones |

| Heating Power: | 11kw |

| Calibrator Material: | High Quality Wear Resistance Copper |

4. (Vacuum Tank):

“Length: 6000mm”

Main Details |

|

| Tank Material: | SUS304 Stainless Steel |

| Other Parts Material: | Vacuum Pipe, Water Pipe Ball Valve, Sealing Flange, Quick-Change Connector are all SUS304 Stainless Steel |

| Calibrator: | Calibrator cooling with glass flow meter |

| Riding Wheel Control: | Riding Wheel Up and Down Adjusted by Reducer |

| Calibrator Material: | High Quality Wear Resistance Copper |

| Cover Type: | Toughened Glass Cover |

| Adjustable Height: | 50mm |

| Adjustable Traverse Distance: | 50mm |

| Adjustable Longitude Distance: | 500mm |

| Moving Motor: | 0.55kw |

| Vacuum Pump Power: | 3kw 3kw |

| Water Pump Power: | 3kw 3kw |

| Cooling Type: | Spray Water |

| Tank Wall Thickness: | 3mm |

| Water level adjust type: | High Stable Water Level Measure |

| Water temperature control: | Thermocouple Induction Valve |

5. (Cooling Tank):

“Length: 6000mm”

Main Details |

|

| Tank Material: | Stainless Steel |

| Riding Wheel Control: | Riding Wheel Up and Down Adjusted by Reducer |

| Motor power: | 3KW |

| Filter: | With Filter |

6. (Haul-off Unit):

Main Details |

|

| Caterpillar: | 2pcs |

| Caterpillar Width: | 108mm |

| Max. Haul off Force: | 13500N |

| Haul off Speed: | 1.3-13m/min |

| Motor Power: | AC motor 1.5KW*2sets, ABB inverter control |

| Effective Haul off Length: | 1800mm |

| Count Length Control: | Haul off count length by encoder |

7. (Cutter):

Main Details |

|

| Motor Power: | 1.5kw |

| Cut Mode: | Blades Without Chip |

| Moving Method of The Platform: | Drive by Pneumatic |

8. (Stacker):

“Length: 6m”

9. (Spare Part):

“For Equipment”

1 Dismantling tools for screw

3 Thermometers

2 Oil seal for gearbox

1 Heating circle of the mouth die

5 2m Thermal couple 2m

2 ceramic adapter-male

8 Anti-High temperature Wire for mould

2 Seal plate for vacuum tank

3 Rubber seal for vacuum tank

30 Nozzle for tanks

1 Vacuum meter

30 φ8 air tube

1 2-position 5-port solenoid valve

5 φ8-three position air connector

2 φ10 to φ8 connector

2 Knife

10 Rubber block for haul-off unit

2 Contactor

“For Tooling”

1 Spanner 200

1 Spanner 375

1 inner hexagon spanner (5-22)

2 little shovel

1 ”—“Type screwdriver

1 ” ” type screwdriver

1 Pliers

1 Knife for cutting plastic pipe

1 Tool box

Reviews

There are no reviews yet.