Semi-automatic Shrink Wrapping Machine

Description

-

Equipment model: rendat-A5000 – Equipment dimension: l5500 × W3500 × H2100mm

-

Furnace channel size: 1800 * 550 * 400 – Maximum size of package: L400 × W250 × H250mm

-

Shrinkage film material: PE – Shrinkage film thickness: 0.03-0.15mm

-

Maximum temperature of heat shrinkable furnace: 100-200 ° Any adjustment.

-

Maximum output per minute: 5-10 packs – Equipment power: 25kW

-

Actual power consumption: 20kW / h -Voltage requirement: 380 / 220 V

-

Equipment weight: 1T

Basic equipment configuration:

-Weilun touch screen, Mitsubishi PLC control system, electrical appliances and switch components of Chint.

-One set of pneumatic components for Yade in Taiwan

-Optoelectronic switch and proximity switch of otonix, South Korea.

-Heat sealing knife casting aluminum heating plate, uniform temperature, long service life, our company special custom.

-The frame is made of high quality carbon steel

-Conveyor belt length: 3250 mm

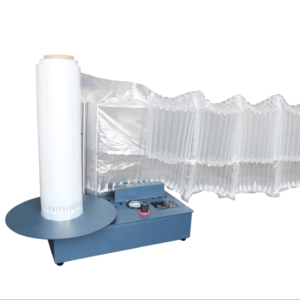

-Winding film packaging.

Product Description:

-Governor speed regulation, two-stage conveying device.

-The whole action of bottle pushing, heat sealing and cutting adopts pneumatic mechanism.

-The induction switch controls the film length.

-Weilun touch screen and Mitsubishi PLC control system greatly increase the reliability of equipment operation.

-The height of the conveyor belt is 900mm, which can also be made according to the requirements of users, with adjustable range ± 50mm

-The conveyor belt pressure can be extended or shortened according to the bottle feeding direction required by users,

Technical conditions and requirements:

1. Package: cuff

Package specification: 3 * 4 /3 * 5 /4 * 6

2. Packaging speed: 5-10 packs

Packaging material: PE heat shrinkable film, width (200-570mm), thickness (0.05-0.12mm)

-Packaging process: conveying – photoelectric detection of feeding mechanism, pushing sleeve film sealing – shrinkage Cooling palletizing

1. Conveying: the packing material enters into the conveyor belt of the sealing machine, and the conveyor belt is provided with an adjustable guardrail. When the package reaches the set position, the conveying stops.

2. Pushing: after the package reaches the pushing position, the pushing cylinder works at the same time to push the package through the sealing line.

3. Film sealing: the package pushed through the sealing thread is pressed by the pressing device above to prevent dumping. After the pushing cylinder is withdrawn, the film sealing cylinder and the film cutting cylinder work at the same time to complete the film covering and sealing.

4. Shrinkage: after the film is covered, the package enters the shrinkage furnace for shrinkage.

5. Cooling: after the package shrinks, it enters the auxiliary rack for stacking after passing through the cooling device at the end of the machine.

Reviews

There are no reviews yet.